Robotics for Carbon Dioxide Removal

Applications, Environments, and the pathways to gigatonne scale

👋 Welcome to Climate Drift: your cheat-sheet to climate. Each edition breaks down real solutions, hard numbers, and career moves for operators, founders, and investors who want impact. For more: Community | Accelerator | Open Climate Firesides | Deep Dives

Hey there 👋

Skander here.

Last time, driftie Alexander showed us how robots are quietly rewiring climate solutions: from building solar farms to Agri-tech.

This week he takes us straight to the moon-shot target: gigatonne-scale carbon dioxide removal (CDR).

Alexander’s spent years hacking together sea-ready machines and MRV toolchains, so expect plenty of nuts-and-bolts realism mixed with his trademark love for sci-fi.

Strap in for:

🌲 Land bots vs. the gigaton gap:

Drone swarms seeding burned forests, soil-sniffing rovers mapping buried carbon, and why seed shortages (not sensors) might be the bottleneck.

🌊 Ocean ops without the seasickness:

Gliders that chase alkalinity plumes, autonomous barges spreading crushed basalt, and the “data rave” needed to prove lasting drawdown.

📈 MRV 2.0:

How sub-$100 sensors, edge AI, and standardized robotic workflows could turn today’s patchy verification into tomorrow’s climate ledger.

⚡ Scaling math that actually pencils

Why labour-light robots slash $/tCO₂, but only if they survive brine, bio-fouling, and 1,000-km service runs.

🚧 Hard truths on durability & circularity

Corrosion, battery end-of-life, and the looming e-waste cliff no one wants to tweet about.

Ready to nerd out on CDR mechs, gigaton math, and the future of CDR?

🌊 Let’s dive in

But first, who is Alexander?

Alexander is a multidisciplinary engineer and designer who transforms ambitious ideas into real-world solutions. With a background spanning mechanical engineering, carbon methodology development, and marine robotics, he's spent his career at the intersection of technical innovation and climate impact.

As CoFounder of Samudra Oceans, he led the development of automation solutions to scale seaweed farming and develop frameworks for their carbon removal potential. His approach combines hands-on prototyping with systems thinking, blending technical expertise with an appreciation for our natural environment and a love of science fiction.

Robotics for Carbon Dioxide Removal

This is a long one again, click the title if you want to read it fully 👆

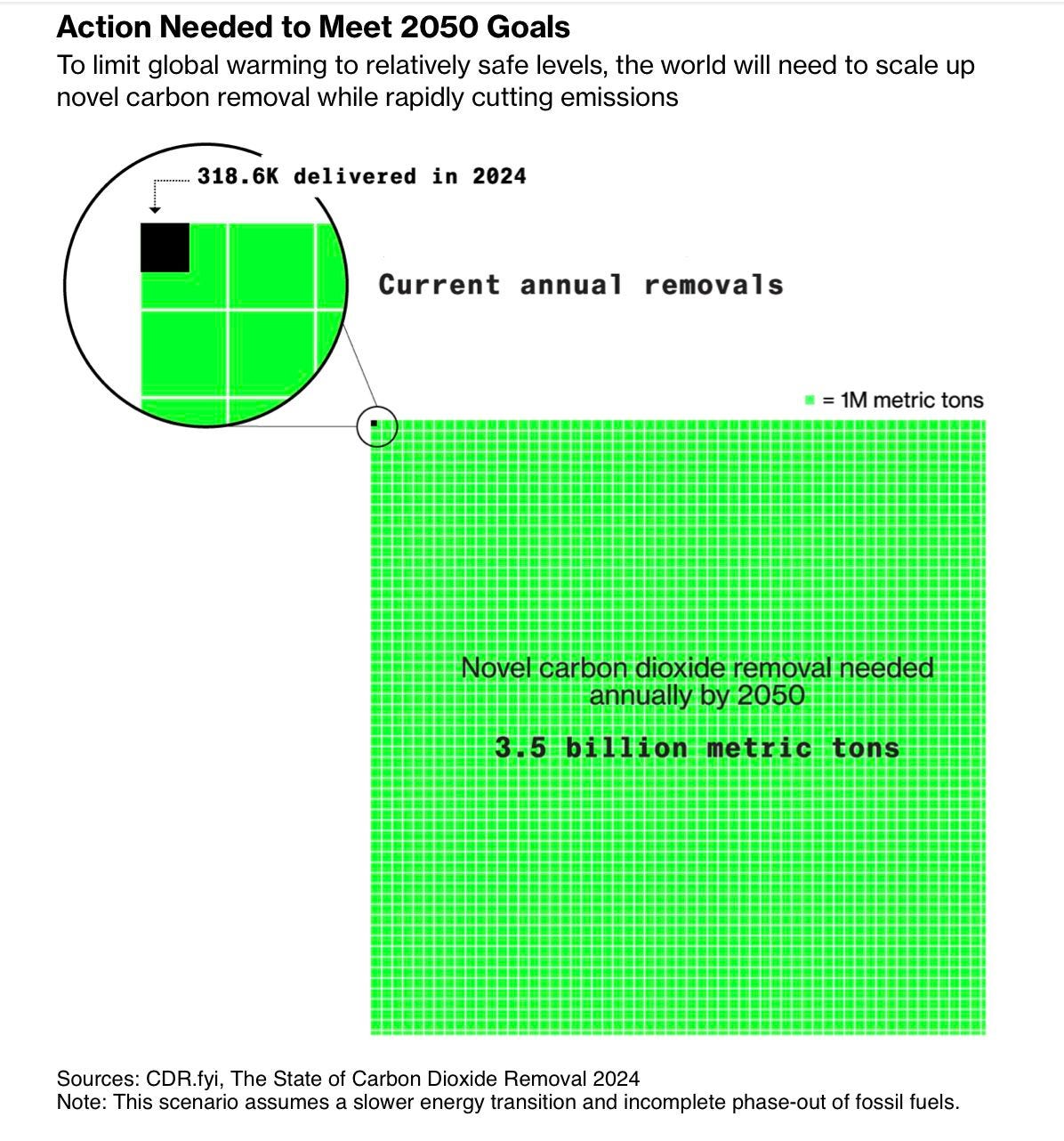

Carbon dioxide removal (CDR) is a fundamental requirement at this point in time. Even if we achieve net zero today, we still have to remove gigatonnes of CO2 from the atmosphere. Current suggestions are that we need to scale CDR to remove 3.5 billion tonnes of CO2 annually by 2050. In 2024, we delivered approximately 319,000 tonnes. Scaling these removals is one of the greatest economic and technical challenges we face in the next thirty years.

Natural systems, like our ocean and forests, represent many of the highest potential options available. Deploying these solutions at climate-relevant scale requires access to vast, often remote or hostile environments, alongside rigorous measurements that can validate carbon storage over centuries.

This is where robotics emerge as an unlock. By combining advanced sensing, autonomous operation, and physical interaction capabilities, robotic systems can break the economic and logistical barriers that have constrained environmental CDR. This piece examines how purpose-built robots are revolutionising terrestrial and oceanic carbon removal pathways. From autonomous tree-planting systems to ocean monitoring platforms, they represent fundamental shifts in how we approach the massive undertaking of drawing down atmospheric carbon and returning our climate system to balance.

What is Carbon Dioxide Removal?

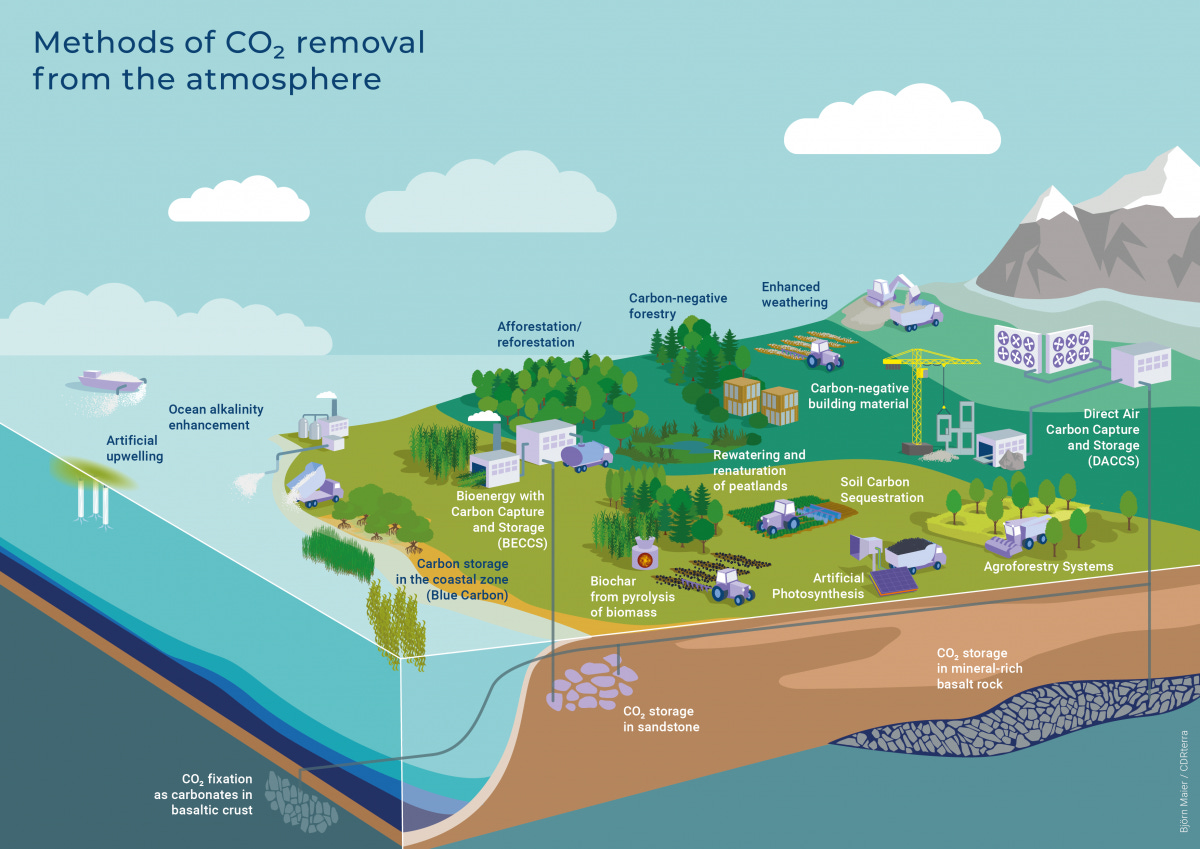

As per the IPCC, Carbon Dioxide removal is any process that captures and durably stores Carbon Dioxide from the atmosphere. In accounting terms, it is a process that is net negative in carbon emissions, or captures more CO2 than it emits. There are three primary pathways to capture and store carbon dioxide from the atmosphere:

The Terrestrial Pathway - CDR projects that take place on and utilise the land for capture and storage of CO2. e.g. reforestation, no-till agriculture, biochar storage

The Oceanic Pathway - CDR projects that use the ocean and ocean systems to capture and store CO2. e.g. Mangrove restoration, Ocean Alkalinity Enhancement

The Technological Pathway - Projects using totally engineered systems for capture and storage. They don't make use of environmental CDR pathways. e.g. Direct Air Capture.

Can Robotics aid CDR?

Using the above framework for categorisation, this piece will look at robotics for CDR in the Terrestrial and Oceanic pathways. They can also play a part in the technological pathway, but due to the nature of these methods, a piece on industrial robotics is better suited to look at it than this piece.

Why these pathways? Because they utilise and enhance existing carbon removal pathways in the environment. They are, at least to some extent, each a form of Environmental CDR. Many of these methods and processes occur over wide areas. Think of the scale of forests! These aren't places that are easy for humans to access and work in, making the projects expensive or slow to deploy.

Even in more accessible locations like farms, the actual impact and visibility of the CDR action is usually invisible. Humans can't easily detect the increase in soil carbon storage for example, but a robot with the right sensors can, and is capable of sampling many more locations in the same amount of time.

Locations can be dangerous to access too. Working in the ocean is inherently higher risk than operating on land. Given that the ocean is already the single largest carbon and heat sink on the planet, we need solutions to manage and enhance it. While the surface is risky, the depths are practically inaccessible to people.

Clearly environmental CDR requires solutions outside human beings to make work. Robotics are one of the solutions we can utilise to unlock, catalyse, and scale these environmental CDR methods all while ensuring we do so responsibly.

What aspects of CDR can robotics play a part in?

Data

Environmental data is fundamental to carbon dioxide removal. It is essential for assessing and siting new projects, and in reporting and verifying carbon removal. It is, in many ways, foundational to all carbon dioxide removal. This proves even more true for methods utilising terrestrial or oceanic pathways, where CDR methods can have variable efficiency based on the location, and background carbon fluxes (the continual release and absorption of CO2 in natural systems) need to be taken into account. For example, soil in one part of the world will have a very different baseline amount of CO2 storage and flux versus another part of the world. Remote and aerial observation with satellites and aerial drones get us some of the way. In-situ robots and IoT systems are then utilised for the sampling required that can't be done remotely. This combination of systems presents a comprehensive set of tools for assessing a project location, compared to extensive human sampling and lab work.

Project Assessment & Siting

CDR project assessment and siting is crucial in the beginning stages of any project. It involves evaluating a potential location and suitability of a CDR process, as well as the environmental, social, and economic impacts of any project developed.

Baseline Establishment & Comparative Analysis

Robots can efficiently collect comprehensive pre-project data to establish accurate carbon baselines, which are crucial for later measuring actual carbon removal achievements. They can efficiently survey multiple potential sites using standardised methods, enabling objective comparison between candidate locations.

Optimised Placement

Robots can gather and analyse extensive geospatial data to identify ideal locations that maximise carbon sequestration while minimising costs or environmental disruptions.

Resource Mapping

Autonomous systems can rapidly survey potential project areas to identify and quantify available resources like suitable soil conditions, mineral deposits for enhanced weathering, or forest growth potential.

Risk Assessment

Robotic surveys can identify potential challenges such as environmental vulnerabilities, accessibility issues, or features that might complicate project implementation.

Impact Analysis

Advanced sensing platforms can collect data on biodiversity, hydrology, and other environmental factors to help to predict potential project impacts beyond carbon removal. In addition, robots can gather information about the local conditions and how any projects could affect nearby communities. Helping to optimise projects for maximum benefit and minimise any negative impacts.

Monitoring, Reporting, and Verification

Monitoring, reporting, and verification (MRV) is still in its infancy as we continue to develop and refine our CDR methods. Each process has its uncertainties at the moment, and their own methods of ensuring that carbon removal has taken place. Many will likely also use models and simulations in conjunction with on site data.

In general, a good MRV process accounts for all emissions, energy use, and environmental and social outcomes from a project. It allows one to determine the net climate benefit of a project and makes clear that the work was done effectively and safely. It is a core framework for a successful project and builds trust for all stakeholders.

Enhanced Data Collection

Robotic systems can access challenging environments and collect data continuously, providing more comprehensive monitoring than manual approaches. For example, autonomous underwater vehicles can measure ocean acidification & alkalinity for marine CDR projects, while aerial drones can survey forestry projects across vast areas.

Improved Accuracy

Advanced sensors on robotic platforms can capture precise measurements of carbon flux, soil carbon content, and other relevant parameters with minimal human intervention, reducing measurement errors.

Real-time Monitoring

Robotics enables continuous observation rather than periodic sampling, capturing temporal variations in carbon sequestration rates and providing early detection of potential issues.

Cost Efficiency

Once deployed, autonomous systems can reduce the labour costs associated with manual monitoring, especially in remote or hazardous locations, making MRV more economically viable at scale.

Standardisation

Robotic monitoring can help establish consistent data collection protocols across different CDR projects, making verification more reliable and comparable between initiatives.

Execution

The use of robotics in execution of the CDR project is dependent on the method. Centralised activities like direct ocean capture, where the activity is done at one specific site, are not ideal for robotics, but distributed activities, like tree planting, seaweed farming, or enhanced rock weathering are areas where robotics can excel. The more remote, hard to access, or risky the area is, the more robotics will be viable as well. Spreading seeds, planting trees, deploying seaweed, all of these are activities that can be performed by a robot, and are currently relatively dirty, low paying jobs.

Precision and Consistency

Robots execute tasks with high precision and consistency, following exact specifications that maximise carbon removal efficiency and repeatability.

Scale and Speed

Autonomous systems can operate continuously and at scales difficult to achieve with human labour alone, accelerating CDR implementation.

Adaptation Capabilities

Advanced robotic systems can adjust operations based on real-time data and conditions, optimising CDR performance as environments change.

Safety Improvements

In higher risk locations like operating at sea, robots can replace human labour, significantly increasing the safety of a project, by minimising the amount of time people need to spend in the field.

Labour Optimisation

Automation of repetitive tasks allows human workers to focus on oversight, quality control, and decision-making roles that require human judgment.

Examples of CDR Robotics

Reforestation / Afforestation

Weighted Average Price of Credit (2023): $16/ tonne CO2

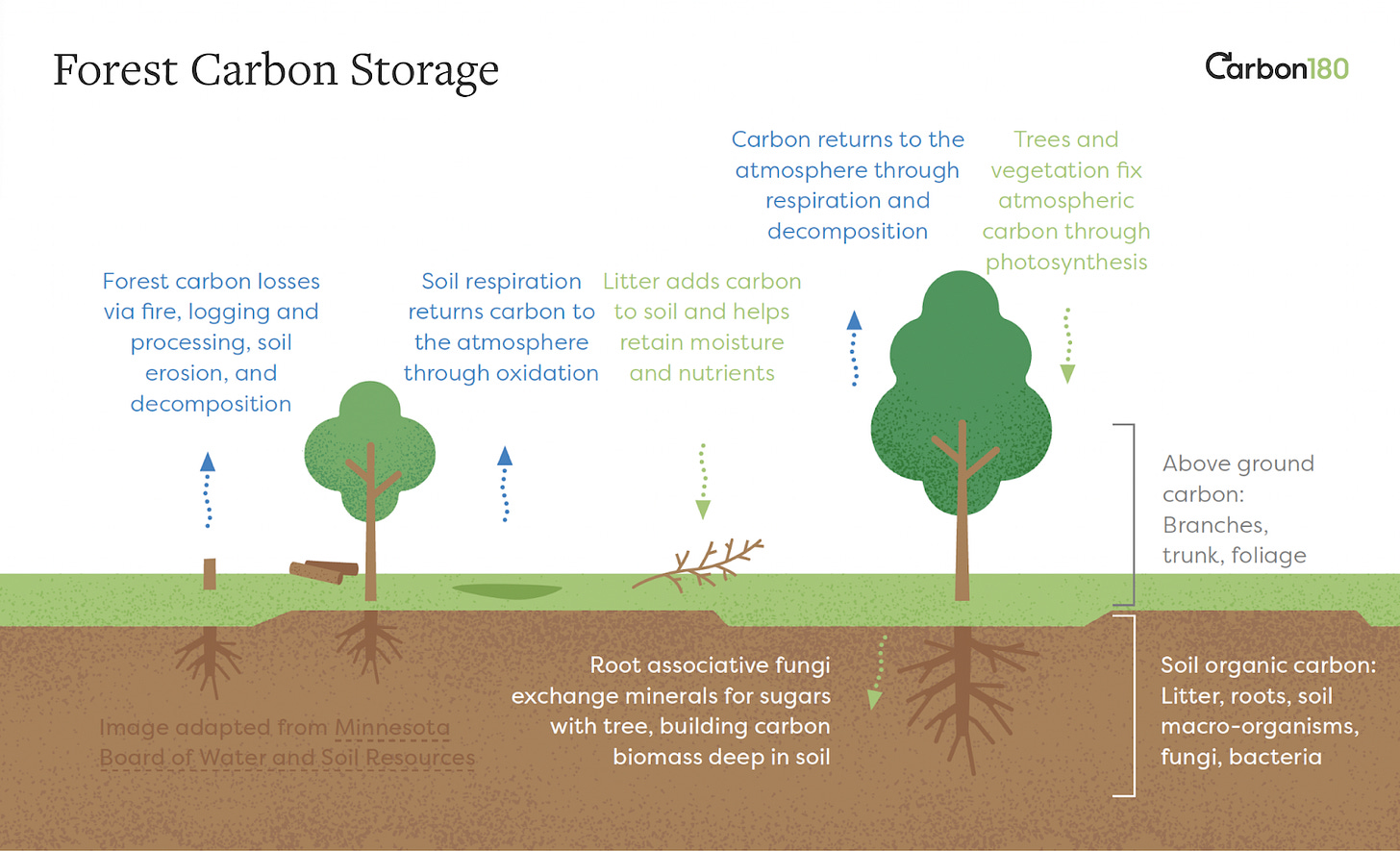

Trees are the poster child for all things good and bad about carbon removal. They are great at naturally soaking up CO2, but are susceptible to fires and other disasters, as well as deforestation. As trees grow, they capture CO2 from the air and use the carbon to form their biomass. Because of their susceptibility to destruction, trees are generally a lower durability carbon credit compared to others, but are cheap to reflect that.

Mass reforestation at scale is highly challenging. It is a labour-intensive and complex process to not just plant trees, but restore the entire forest ecosystem. Data is needed to understand the correct choice of species for the site. Labour to gather the data, perform the planting, and continued management and monitoring of the site is expensive and complex.

In terms of site monitoring and management, GIS data collection has expanded significantly. Satellite and drone surveys are common today, a clear unlock provided by robotic and other automated sensing systems. Drone mounted LIDAR and hyperspectral imaging, coupled with in-situ measurements are becoming essential to forestry management. Specific to carbon removal, these technologies allow remote measurement of growth and carbon uptake into the biomass.

Looking at planting itself, there have been a lot of methods trialled, from direct seeding, to 'seed bombs.' The goal is twofold, to cover the area as cost effectively as possible, and to get the most efficient usage of seeds. Seed shortages are one of the biggest challenges facing mass reforestation at the moment. Solutions that can drive higher efficiencies on both aspects are needed. One method has been aerial seeding, a technique using aerial drones to scatter seeds across a landscape. This is a highly cost-effective technique for large scale planting, but does suffer from lower germination rates and seed loss. Companies like AirSeed Technologies and Dendra Systems are developing solutions to account for these weaknesses. Alternatively, solutions to automate direct seeding and seedling transplantation are less developed, but should have higher germination rates. Companies like LandLife and Trovador, are developing robot solutions for direct planting. On this front it is still early days, but solutions like these look promising.

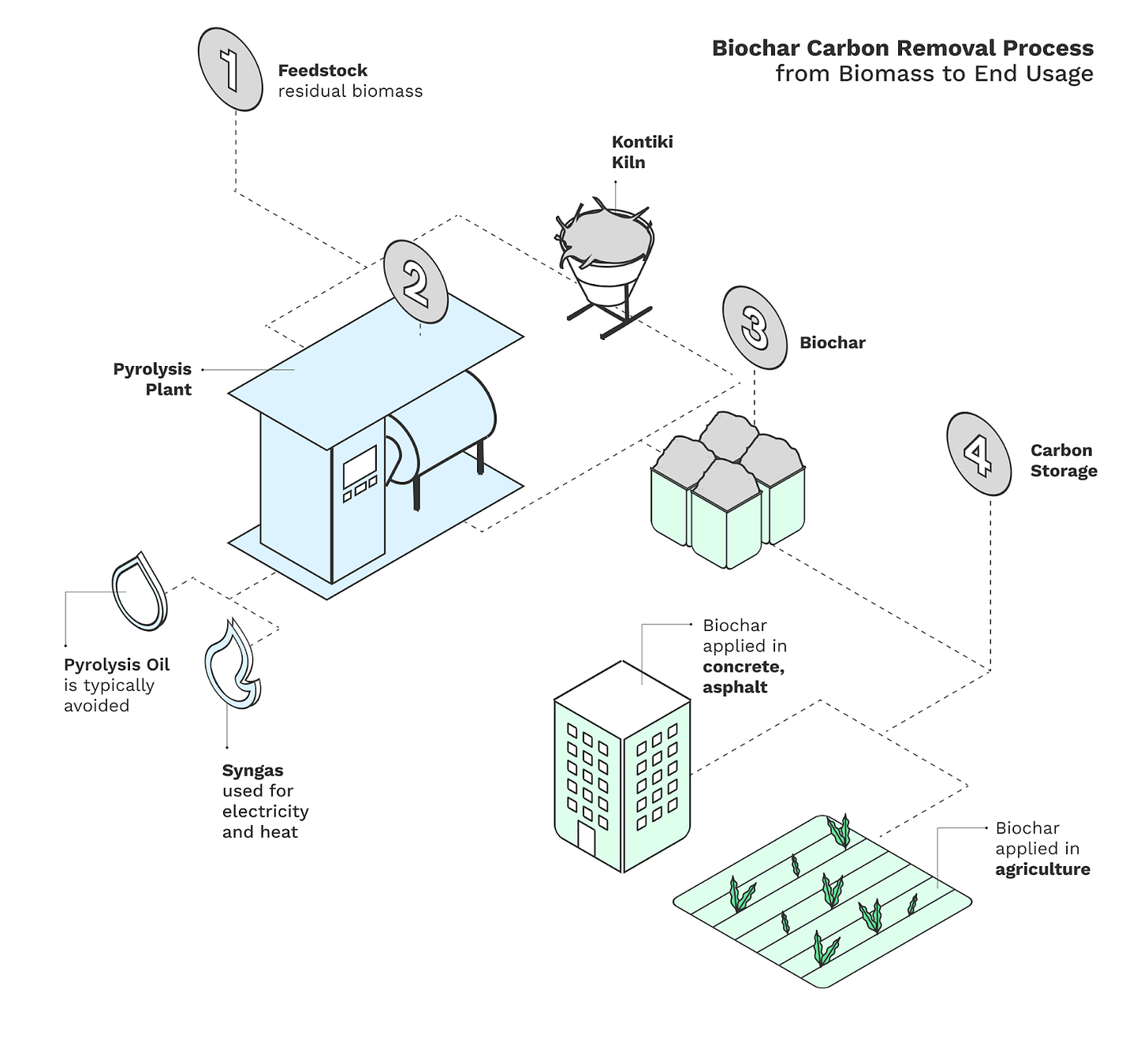

Biochar Soil Storage

Weighted Average Price of Credit (2023): $131 /tonne CO2

Biochar is a CDR process that falls within the category of Biomass Carbon Removal and Storage (BiCRS). It uses photosynthetic organisms to capture CO2 from the air and convert it into biomass. To store that biomass carbon, we need to convert it into a format that is much more resistant to degradation. Heating the biomass in the absence of oxygen prevents burning and creates the biochar. Potentially capable of storing carbon for 1000+ years when added to soil.

In terms of execution, one needs to collect the biomass, dry it, pyrolyse it, then take it back to the field and spread and store it. These are a lot of steps to take! For many biochar companies, the biomass used is the residuals left from harvesting crops. These residues aren't collected at harvest, so would require an additional 'harvest' on the farm, at least until things scale enough to change harvest practices. Once converted, the biochar needs to be returned to the field and spread onto and into the soil.

Applied Carbon has designed a robotic system capable of performing all of these steps out in the field! It collects the biomass, processes it, and stores it in the soil, all using one system.

On the data side of things, soil sampling is a huge part of the initial assessment work on biochar, as well as testing the longer term storage and stability of the char. Soil sampling is fairly labour-intensive at the moment, especially for high quality and precision work. It requires taking the soil sample from the field, to a lab capable of performing the assessment. Why not bring the lab to the field? Mobile robots could sample the field area as needed, or static robots like Yardstick PBC can provide time series data.

Marine CDR

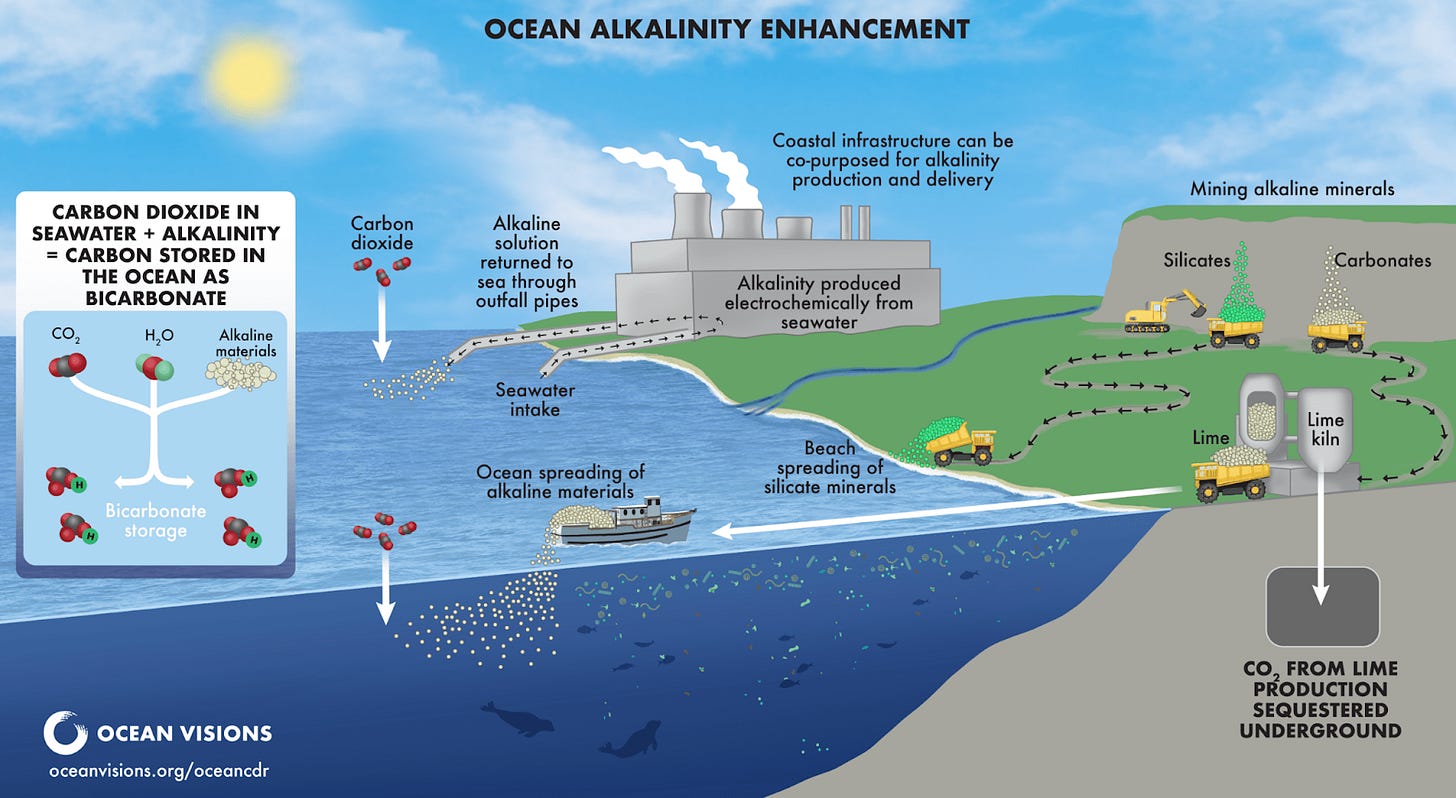

Ocean Alkalinity Enhancement

Weighted Average Price of Credit (2023): $1,608 /tonne CO2

Ocean Alkalinity Enhancement (OAE) is a process of adding alkaline substances to seawater to increase the rate of CO2 dissolution. This can be done out at sea, on the coastline, or in reactors, generally by adding crushed alkaline minerals, but also via electrochemical methods. By making the seawater more alkaline, it increases the 'air-sea flux', the rate at which CO2 dissolves in the water to form bicarbonate and carbonic acid. These are stable in the range of 10,000 years so present a highly attractive form of CDR.

Because of the open system of the ocean, we can't measure and account for every single variable and change. We will have to model and simulate the impact and efficiency of ocean CDR. With OAE, the initial chemistry shift in the water happens instantly, but the additional absorption of CO2 takes time to happen (up to several years). This happens far away from the initial application site due to ocean circulation, but if the treated water moves away from the surface it can't absorb the CO2. With our current knowledge we know that in different regions of the world, at different times of the year this process varies in efficacy. Carbonplan has an amazing explainer on the process that I highly recommend reading to understand more.

So, why robotics for OAE then? Just because we can't measure everything, doesn't mean we shouldn't take as many measurements as we can. To refine our models and simulations, we need significantly more data on ocean currents and movement, pH, total alkalinity, and pCO2, etc. These need to be taken over the entire ocean area. Ocean Gliders, Argo floats, and other robotic platforms all need to be deployed to take higher density measurements to better refine our models. Saildrone, Sofar Ocean and many others are helping to fill this data collection gap.

On the execution side, it is still early to determine how precise in timing and location our deployments need to be, but like the monitoring, we have such a high spatial area over which we can act. These areas are risky and time-consuming for humans to be involved with. Robotic boats and barges could be employed to decrease the human requirements for executing OAE at sea, or spreading minerals on the coastline like Planetary does.

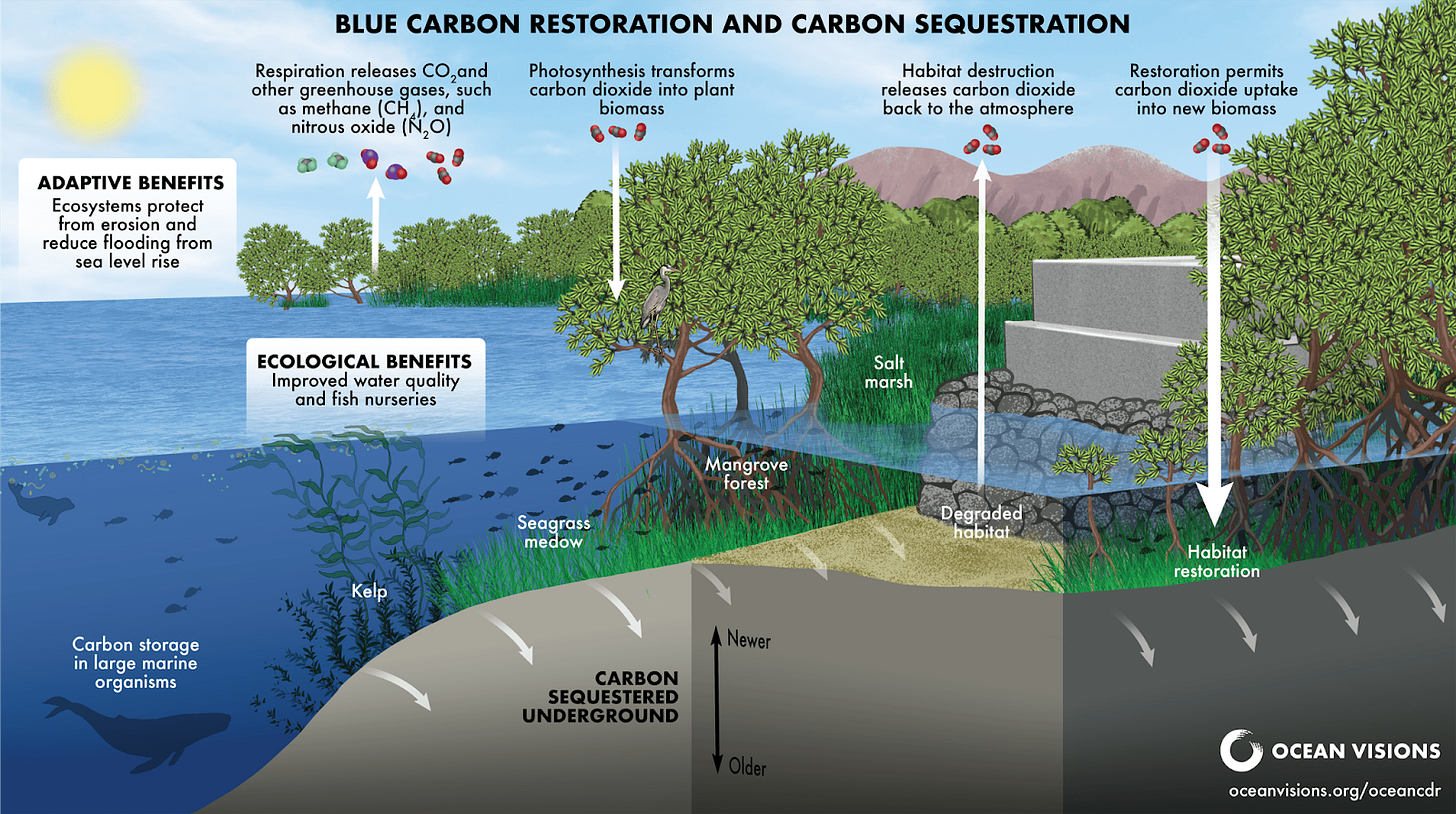

Seagrass Restoration and Management

Weighted Average Price of Credit (2023): Unknown

Seagrasses are part of what is referred to as 'traditional blue carbon' alongside mangroves and salt marshes. They fix CO2 via photosynthesis, and trap that organic carbon in their roots and the marine sediment for, up to, thousands of years. Seagrass coverage is estimated at approximately 160,000 sq km of coverage, and they are reputed to store approximately 140 tonnes of Carbon per hectare(500 tonnes CO2 equivalent) on average in the soils and sediments below them. They are a niche, but powerful option for carbon removal and storage, as well as providing a wide range of co-benefits.

It is suggested that we lose about 1.5% of our seagrasses per year, with much of the stored carbon being released when the seagrass is lost. We need to restore and replant them, not just to capture more carbon, but to prevent the release of historic carbon already stored. What does it cost to restore seagrasses at the moment? Estimates from researchers in Australia are as high as US$399,532 per hectare!! It's probably cheaper than this in low income regions of the world, but still shows how truly expensive the process is. With an estimated CO2 capture per hectare per year is about 6 tonnes CO2, that carbon credit would cost nearly $67,000 per tonne! And that's before we even consider the emissions necessary to restore that seagrass. Clearly, we need to change our approach to make this viable at scale.

With long term changes in seagrass coverage, aerial and satellite imagery are highly capable at tracking this. Seagrasses only occur in the shallows of the ocean, where enough light can penetrate, so can be visibly seen from outside the water. This geospatial data is great for understanding the global changes happening, but we really need to get into the water to make an actual impact.

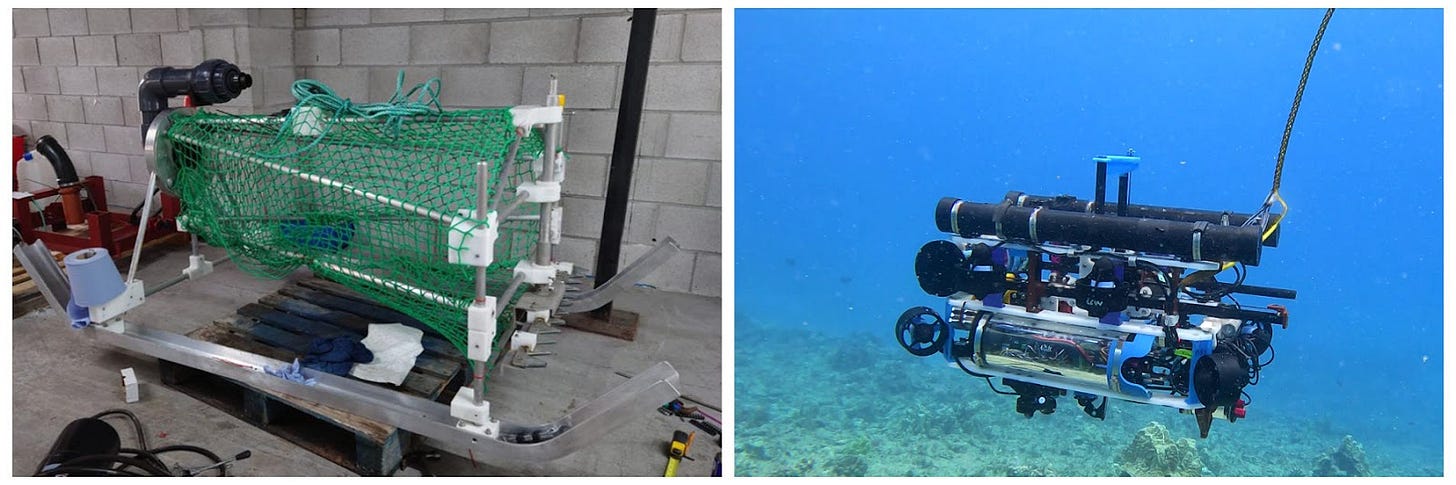

Robotics have the potential to turbocharge and unlock Seagrass restoration. Companies like Ulysses and Reefgen are examples of solutions in development. They both appear focused on replanting of seagrasses initially, and it will be great to see these expand. Researchers at the Seagrass Ecosystem Research Group are looking at wider engineered applications like seed collection and processing.

Looking further, methods like sediment coring are still manually done by human divers. This is a process that allows scientists to see what carbon accumulation has happened within the seagrass. It would be great to see some automation solutions deployed here to drastically increase the amount of data we have.

The Challenges of Robotics for CDR

Environmental Challenges

We talk about how challenging and risky these environments are for human beings, but they are just as harsh for robotics. Wave action, rain, snow, wind, corrosion, these are just some of the problems that are faced when trying to build something capable of operating out in the environment. Can we build something able to survive for a number of years in these environments? What is the cost of doing so?

Engineering & Technology Challenges

Not only do the robots need to survive in the environment, but they also need to be able to perform the action. Creating grippers and sensors and actuators capable of acting or measuring at the precision needed is hard! For example, today, a sensor to measure CO2 in seawater costs well over $10,000 USD. In soil, do we have the sensors necessary to replicate what we can measure in the lab?

Economic Challenges

We've mentioned above the cost per tonne for each method of CDR. The robotics need to be cost-effective enough to not only make them viable to use on the projects, but also bring the cost per tonne of emissions.

Maintenance Challenges

Solutions operating in truly inaccessible locations, like the middle of the ocean or deep in the forest, need to be able to survive for a long time without access or maintenance. If too fragile or in need of too much human intervention to keep them working, then these solutions defeat the purpose for which they've been made.

Closing

As we’ve seen here, the utilisation of robotics with environmental carbon dioxide removal can be a critical unlock to the process. The examples above clearly show how these solutions can potentially increase access, reduce operational costs and drastically improve data collection. Key aspects to solve the project assessment, MRV, and project execution challenges.

Carbon dioxide removal is still a nascent industry and practice, and robotics for CDR are even more nascent. Designing solutions for an industry that has yet to figure itself out is a fraught endeavour but we need to use every tool at our disposal, given the urgency of climate action. We have the technology, now we need to keep building and applying it to accelerate capacity development.

Scaling CDR will require wide ranging interdisciplinary collaboration. Robotics and general automation engineering is just a part of this work, but hopefully this piece shows just how impactful it can be.

Let’s keep the conversation going. Whether you're building in this space, investing in it, or just fascinated by the intersection of automation and climate action, reach out. These examples only scratch the surface of what’s possible and what’s being built. Some areas I’d love to hear about are:

Applications and solutions I haven’t covered

Real world deployment and scaling challenges

Life cycle assessments of robotic vs traditional operations

Economic and business models that make robotics viable

What to chat? Find me here

Resources & Further Reading

State of CDR Report - global assessment and reporting on the state of CDR and the gaps. (Note that all CDR pricing in this piece is taken from here)

CDRPrimer - great digital book and primer on all things carbon dioxide removal

CDR.FYI - carbon removal market reporting and leaderboard

Carbon180 - CDR policy NGO with great explainers of the whole process and industry

Ocean Visions - Ocean CDR specific platform

Carbonplan - central platform for CDR data and science. Great detailed explainers on many CDR processes, their feasibility, potential, and challenges.

Climagination Substack - Jason Grillo’s Substack looking at the carbon markets

Inevitable & Obvious - Paul Gambill’s substack on carbon removals

For more Climate Drift: Community | Accelerator | Open Climate Firesides | Deep Dives